Industrial Background / Client Info

After more than 60 years in business, our team here at Sanlo is ready for just about anything. That’s why when one of the top names in specialty vehicle manufacturing contacted us about a custom cable assembly to meet their needs, we assured them we were the right people for the job!

This manufacturer, well known for their high quality products, fast turn around, and unique applications, invited us into their plant to get a real world idea of exactly how our cable assembly would be getting used and to help pinpoint any improvements we could make. Our customer challenged us to find cost saving alternatives while designing around their needs in a timely manner, as their due dates and timelines approached quickly. Our team was quick to visit our customer, send out updated quotes accordingly, send out samples, and adjust our design as the customer reported back on sample testing.

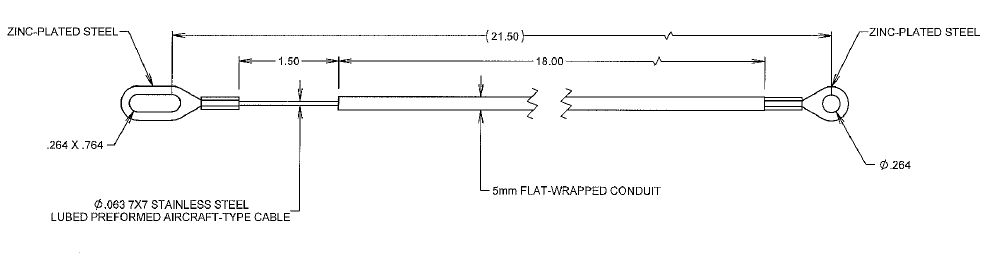

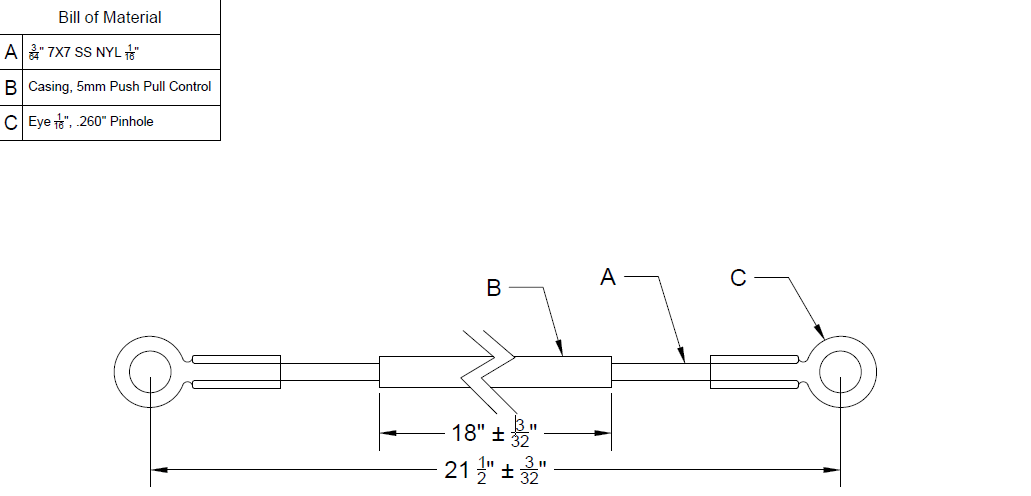

Our customer originally came to us with an “eye-eye assembly” which included a costly custom slotted eye terminal. The custom eye not only drove costs up, but lead times as well. With a demand for 150 pieces a week, our customer could not wait on custom stamping to produce this eye and needed alternatives fast.

Project Details

- Cable assembly to be designed around a door actuating solenoid

- Push-pull style assembly to create a mechanical alternative in the case of failure

- Design must allow for 0.5” of travel

Solution Provided

Our Sanlo team incorporated Sanlo standard alternative parts in order to reduce lead time and cost throughout the project, while still meeting all the needs of the customer. We were capable of providing a 27% savings per piece overall, for an assembly that can now be used company wide. Our design also allowed our customer to keep their original solenoid design without any costly adjustments. The finished assembly is now a “push-pull” style assembly, where cable is threaded through conduit, with standard fittings on both ends terminating the cable. Our original visit was within a weeks notice, and only a few days followed before we sent out our first prototypes, thanks to the speediness of our production team. Without our quick action, this is a project that could have failed in the long run. Along the way, we met a great team of engineers, who were kind enough to leave us with a personal sentiment at the end of all our testing, and ultimately made the whole thing worth it!

Thank you both so much for the quick turnaround through this whole thing. The plan is for this to be a very high-usage item starting as soon as we can get them, which is why I think this is getting so much attention so quickly. We appreciate the support in getting a HUGE upgrade over what we’re using now!

Matt, Mechanical Design Engineer